Bulk Purchase of Paraffin: A Comprehensive Guide

What You Will Discover in This Guide

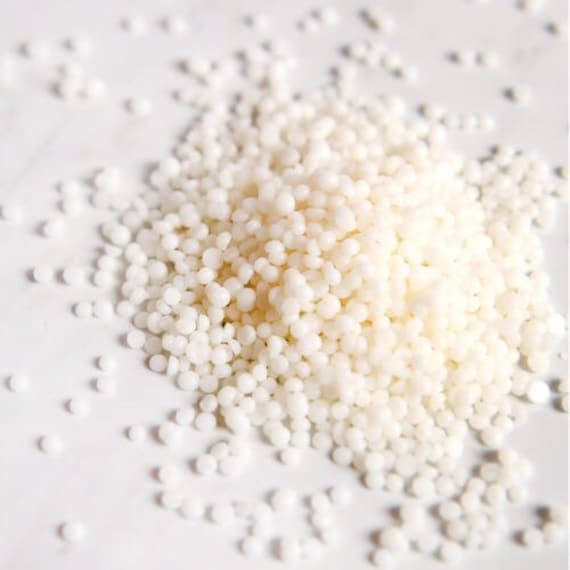

Introduction to Paraffin

Paraffin is a solid, white, odorless hydrocarbon compound that is naturally derived from crude oil. It can also be synthetically produced through petrochemical processes. Due to its unique properties such as low melting point, non-reactivity with many chemicals, and thermal insulation properties, paraffin finds extensive applications in various industries, including candle making, cosmetics, food packaging, and electrical insulation.

We will now explain the types of paraffin and their respective applications, as well as introduce methods for purchasing paraffin affordably and in bulk.

Types of Paraffin

Paraffin can be categorized based on its state (solid and liquid) or molecular weight (light and heavy), each with distinct features and applications. Here’s a detailed explanation of each type:

Solid Paraffin

Solid paraffin is a white or colorless, odorless substance with high adhesiveness that is solid at room temperature and insoluble in water. It has a melting point between 46°C to 68°C and exhibits high flexibility and moldability, making it suitable for various industries:

- Candle Making: This type of paraffin, with its high melting point, slows down the burning rate of candles. It is also cost-effective, easy to mold, and capable of retaining scents and fragrances, making it popular in candle production.

- Paraffin Wax Paper: Packaging papers coated with wax prevent moisture from reaching food items, thereby preserving them. This makes paraffin wax paper widely used in food and produce packaging.

- Textile Industry: Solid paraffin is used in the textile industry for waxing threads.

Important Note: While solid paraffin is generally considered a non-toxic and safe material, prolonged skin contact can cause irritation. It’s recommended to take safety precautions, such as wearing gloves and protective eyewear when handling solid paraffin. Also, remember that overheating paraffin can release harmful fumes.

Liquid Paraffin

Liquid paraffin is a clear, odorless substance with low to medium viscosity, resistant to oxidation and thermal decomposition, remaining liquid at room temperature and insoluble in water. Its applications include:

- Industrial Lubricants: Liquid paraffin is used as a lubricant and base oil in some machinery.

- Cosmetic Products: Due to its mild and non-irritating properties, liquid paraffin is used as an emollient in baby oils and other lotions and creams to protect and moisturize the skin.

- Pharmaceuticals: It is used as a laxative to ease stool passage and treat constipation.

- Plastics Industry: Liquid paraffin acts as a plasticizer and stabilizer in plastic production.

Chlorinated Paraffin

Chlorinated paraffin is a colorless, odorless compound with high melting and boiling points, excellent flame resistance, high thermal stability, good chemical resistance, and serves as a plasticizer and stabilizer in various industries. Its applications include:

- Heat-Resistant Plastics: Used as a flame retardant in plastics, resins, and other flammable materials.

- Plasticizers: Enhance flexibility and reduce brittleness in plastics.

- Lubricants: Employed to reduce friction between moving surfaces, particularly useful under high temperatures or harsh chemical conditions.

- Wax: Essential in making candles, creams, and soaps.

- Insecticides: Certain chlorinated paraffins act as insecticides by disrupting insect nervous systems, leading to their death.

- Concrete Additives: Used to increase water resistance and reduce permeability in concrete, also aiding in creating small pores to reduce its weight.

- Fire Retardant: Applied in various industries as a flame retardant in plastics, resins, rubbers, and other flammable materials by forming a protective layer on surfaces to prevent thermal decomposition and ignition.

Microcrystalline Paraffin

Microcrystalline paraffin is colorless, odorless, with a high melting point, more flexible than regular paraffin, resistant to oils and chemicals, and possesses high strength and adhesiveness. Its applications include:

- Candle Making: A primary material in candle production.

- Food Packaging: Used for packaging and coating fruits and other food items to extend their shelf life.

- Paper Industry: Enhances water and moisture resistance of paper products.

- Textile Industry: Employed for waterproofing and strengthening fabrics.

- Cosmetics Industry: Used as a softening and moisturizing agent in creams, lotions, and other cosmetic products.

- Rubber Industry: Acts as a softener in rubber production.

- Construction: Functions as a moisture barrier in building materials.

- Wax Production: Utilized in making protective waxes for shoes and cars.

Light Paraffin

Light paraffin, primarily known as liquid paraffin, has a lower molecular weight and remains liquid at room temperature. It has numerous industrial applications:

- Lubricants

- Cosmetics and Personal Care

- Pharmaceuticals

- Plastics Industry

Heavy Paraffin

Heavy paraffin, primarily known as solid paraffin, has a higher molecular weight and remains solid at room temperature, used as paraffin wax in various applications:

- Candle Making

- Food Packaging

- Textile Industry

- Oil and Gas Industry

These are the types of paraffin and their applications in different industries.

Comparison of Paraffin Types

This comparison outlines the primary applications of different types of paraffin, providing a clear understanding of their uses in various industries.

Categorization of Paraffins Based on Physical Structure

Paraffins are divided into various types based on their physical shape and structure, each having distinct characteristics and applications. Below, we explore the differences between crystalline, powdered, and gel paraffin.

Crystalline Paraffin

- Features:

- Structure: Crystalline paraffin has a regular, crystalline molecular structure, giving it a transparent and glassy appearance.

- Melting Point: This type of paraffin has a higher melting point and is usually solid at room temperature.

- Transparency: Its high transparency makes it suitable for applications requiring a clear appearance.

- Applications:

- Candle Making: Used for making decorative and ornamental candles due to its clarity and beauty.

- Cosmetic Products: Used in the production of some cosmetic products.

- Protective Coatings: Serves as a protective layer in certain industrial applications.

- Features:

Powdered Paraffin

- Features:

- Structure: Produced in fine, powdery particles.

- Melting Point: Generally has a lower melting point compared to crystalline paraffin and melts easily.

- Mixability: Easily mixes with other materials, making it useful as an additive in various products.

- Applications:

- Additive in Products: Used as an additive in the production of plastics, rubbers, and paints.

- Coatings and Protective Materials: Employed in the production of water and oil-resistant coatings.

- Pharmaceutical and Food Industries: Used as an excipient in tablet and capsule production and as a protective coating in food packaging.

- Features:

Gel Paraffin

- Features:

- Structure: Has a semi-solid, gel-like structure that provides flexibility and softness.

- Transparency: Transparent with a glossy and smooth appearance.

- Melting Point: Has a lower melting point compared to solid paraffin and softens at lower temperatures.

- Applications:

- Candle Making: Used for making gel and decorative candles due to its clarity and flexibility.

- Cosmetic and Personal Care Products: Used in the production of gels, creams, and other cosmetic products.

- Decorations and Handicrafts: Utilized in making decorative items and handmade crafts.

- Features:

Benefits of Bulk Purchasing Paraffin

Buying paraffin in bulk can offer numerous advantages for consumers and industries. These benefits can help businesses enhance their efficiency and profitability while also mitigating risks associated with sourcing raw materials. The most significant advantages of bulk purchasing include:

Cost Reduction:

- Volume Discounts: Bulk purchases often come with volume discounts, reducing the cost per unit of the product.

Increased Bargaining Power:

- Negotiation Leverage: Buying in bulk gives businesses greater negotiating power with suppliers, which can lead to better contract terms.

Inventory Assurance:

- Stock Availability: Maintaining a sufficient stock of paraffin in the warehouse ensures that the business won’t face shortages if supply chain issues arise. This also reduces the need for frequent reordering and saves time.

Reduced Transportation Costs:

- Optimized Shipping: Bulk buying can lower transportation costs by reducing the number of shipments and utilizing lower bulk shipping rates.

Consistent Quality:

- Uniform Quality: Purchasing in bulk from a reliable source ensures consistent quality and reduces variability, resulting in a more uniform final product.

These benefits make bulk purchasing an attractive option for businesses looking to streamline their operations and secure a reliable supply of high-quality paraffin.

Important Considerations for Bulk Purchasing Paraffin

Quality Assessment

- Ensure the paraffin meets necessary standards and certifications.

- Request quality analysis and test results (such as melting point, viscosity, color, and purity) from the supplier.

- Verify that the type of paraffin (solid, liquid, chlorinated, microcrystalline, light, or heavy) matches your specific business needs.

Choosing a Reliable Supplier

- Check the supplier’s track record and reputation in the market.

- Use reviews and experiences from previous customers.

- Evaluate the supplier’s guarantees and commitments regarding quality and timely delivery.

Negotiating Price and Payment Terms

- Compare prices among different suppliers.

- Negotiate for favorable and flexible payment terms, such as installment payments or discounts for upfront payments.

Reviewing Shipping Conditions

- Compare and review transportation costs.

- Ensure that delivery conditions (delivery time, location, transportation responsibilities) are clearly defined and suitable.

- Consider transport insurance to cover potential damages.

Environmental and Health Considerations

- Ensure that the production and transportation of paraffin comply with environmental standards.

- Pay attention to health and safety issues, especially in sensitive environments like the food and pharmaceutical industries.

By following these guidelines, you can manage bulk paraffin purchases more effectively and take advantage of the associated benefits.

Baramen: Supporting Small and Medium-Sized Enterprises

Baramen provides a reliable, trustworthy, and dynamic platform for bulk commodity transactions. You can search for the products you need on the website and compare prices. If the desired product is not available on the site, you can submit a supply request. This request will be sent to suppliers, who will then provide their price offers after reviewing it. You can compare these offers and choose the best one to finalize your order. Throughout the pre-order process, negotiation between parties is possible through Baramen’s chat feature.